160000 Bags/8H Full Automatic Fried Instant Noodle Processing Line

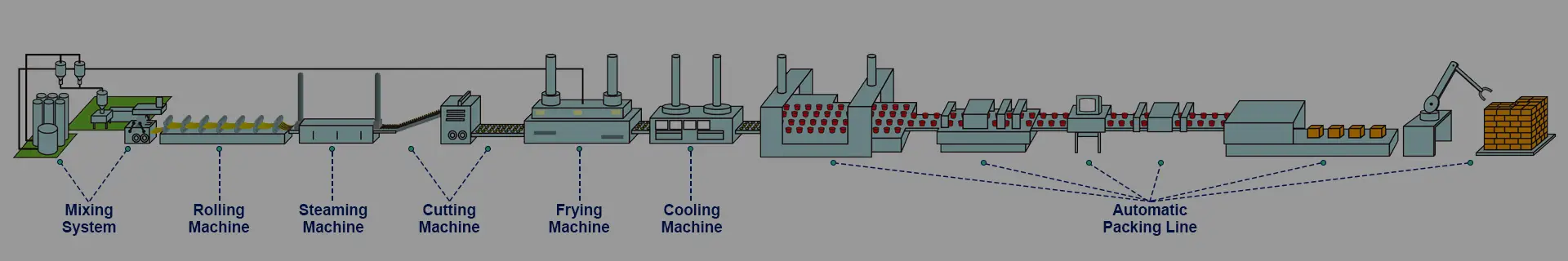

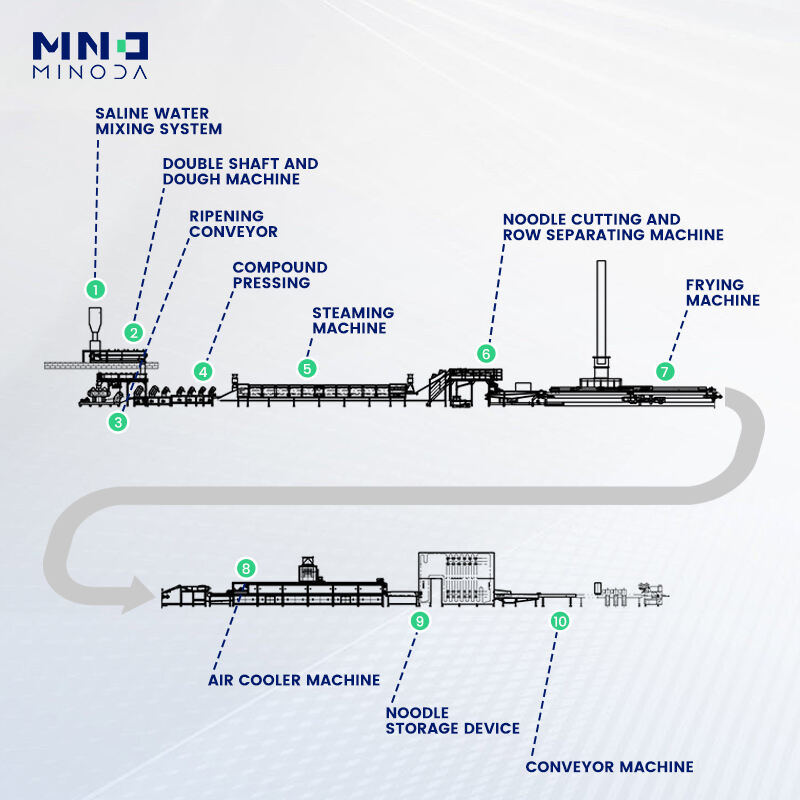

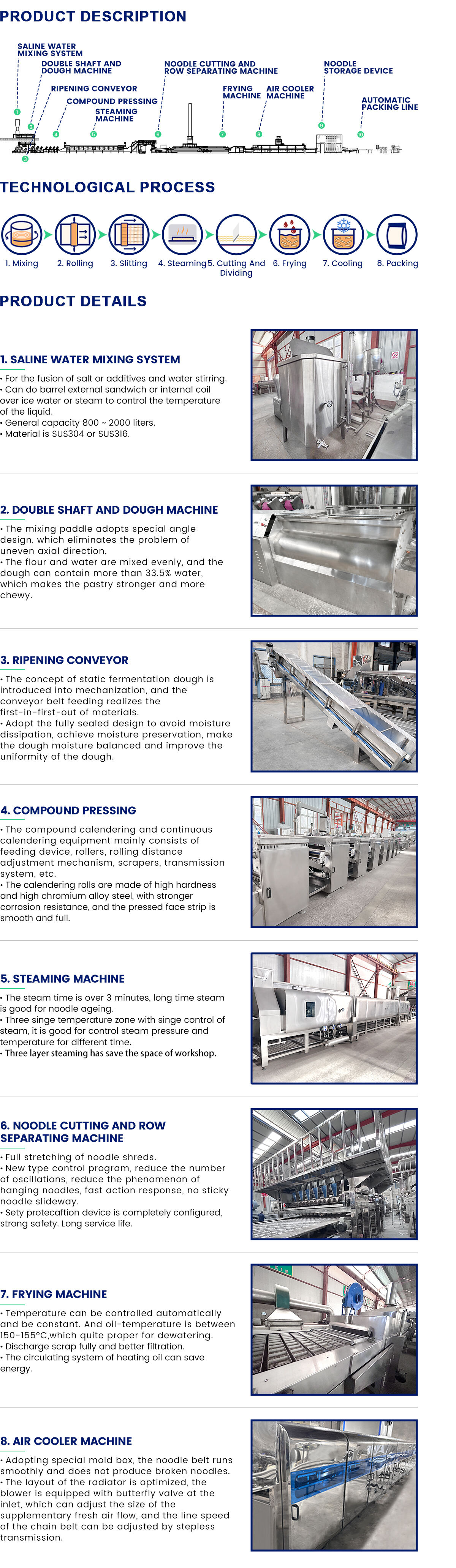

Our fried instant noodle production line has perfect technology, compact structure, stable and reliable performance. The production from flour to finished product is automatically completed at one time, with high automation procedures, energy saving. We have over 12 years’ experience in development and manufacture of instant noodle production line enable us to provide reliable and valuable customized solutions. We enjoy high reputations from our new and old customers at home and abroad, rely on advanced technology, steady quality, reasonable price and excellent services.

- Overview

- Recommended Products

Core Advantage of Our Instant Noodle Production Line:

● The precision gap of the cutting knife is less than 2 millimeters, a good cutting knife can cut softer pieces, and small dents can be formed on the soft dough when frying, so that the noodles tastes more delicious.

● Rolling Machine Roller: Through special treatment of the roller surface, it is not easy to rust, and the thickness of the pressed dough is more uniform.

● The temperature in the steaming box is uniform, and the local temperature will not be too high or too low. The internal temperature of the steam box is between 105 and 145 degrees, and the external body surface temperature is about 35 degrees. Minimize energy consumption.

● Steam recovery and fuel saving device, the steam energy consumption and raw material fuel consumption can be reduced, and the steam energy can be reduced by 70% through the steam recovery device.

|

Capacity |

Power |

Steam consumption |

Dimension (multi- layer steamer) |

Worker |

|

30,000bags/8h |

42kw |

800-1000 kg/h |

40*5*4m |

4 |

|

60,000bags/8h |

56kw |

1200-1400 kg/h |

45*5*4m |

4 |

|

80,000bags/8h |

68kw |

1600-1800 kg/h |

55*6*4m |

5 |

|

120,000bags/8h |

83kw |

2000-2200 kg/h |

65*6*4m |

5 |

|

160,000bags/8h |

106kw |

2400-2600 kg/h |

75*7*4.5m |

5 |

|

200,000bags/8h |

114kw |

2800-3000 kg/h |

80*8*4.5m |

6 |

|

250,000bags/8h |

125kw |

3200-3400 kg/h |

90*8*4.5m |

6 |

|

300,000bags/8h |

140kw |

3600-3800 kg/h |

90*10*4.5m |

6 |

EN

EN

RU

RU

AR

AR

ID

ID

VI

VI

MS

MS

TH

TH

KK

KK

UZ

UZ

TR

TR

ES

ES

FR

FR

JA

JA

KO

KO

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

DE

DE

EL

EL

HI

HI

IT

IT

NO

NO

PL

PL

PT

PT

RO

RO

SV

SV

TL

TL

IW

IW

SR

SR

SK

SK

SL

SL

UK

UK

BN

BN

KM

KM

MY

MY

KY

KY