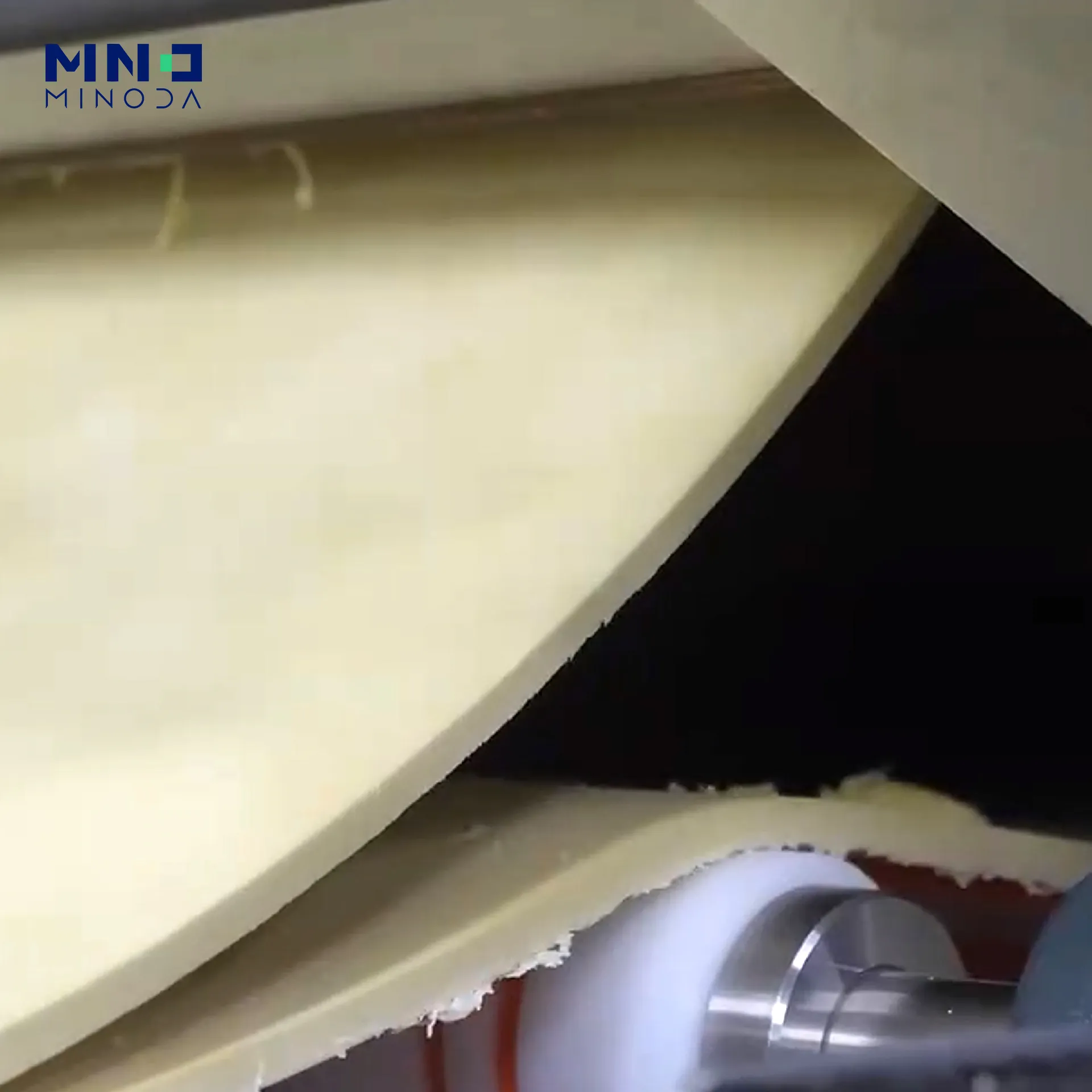

High Production Capacity

The High-Capacity Fast Noodle Production Line is designed to maximize production rates. With advanced automation and efficient processing, it ensures a consistent output of noodles with minimal manual intervention. This allows manufacturers to meet high demand without sacrificing quality. The system is versatile, accommodating various noodle types, from instant varieties to gourmet options, which makes it indispensable for businesses aiming to expand their product lines. Additionally, its modular design allows for easy upgrades, ensuring your investment remains viable in a rapidly changing market.