Enhanced Product Quality

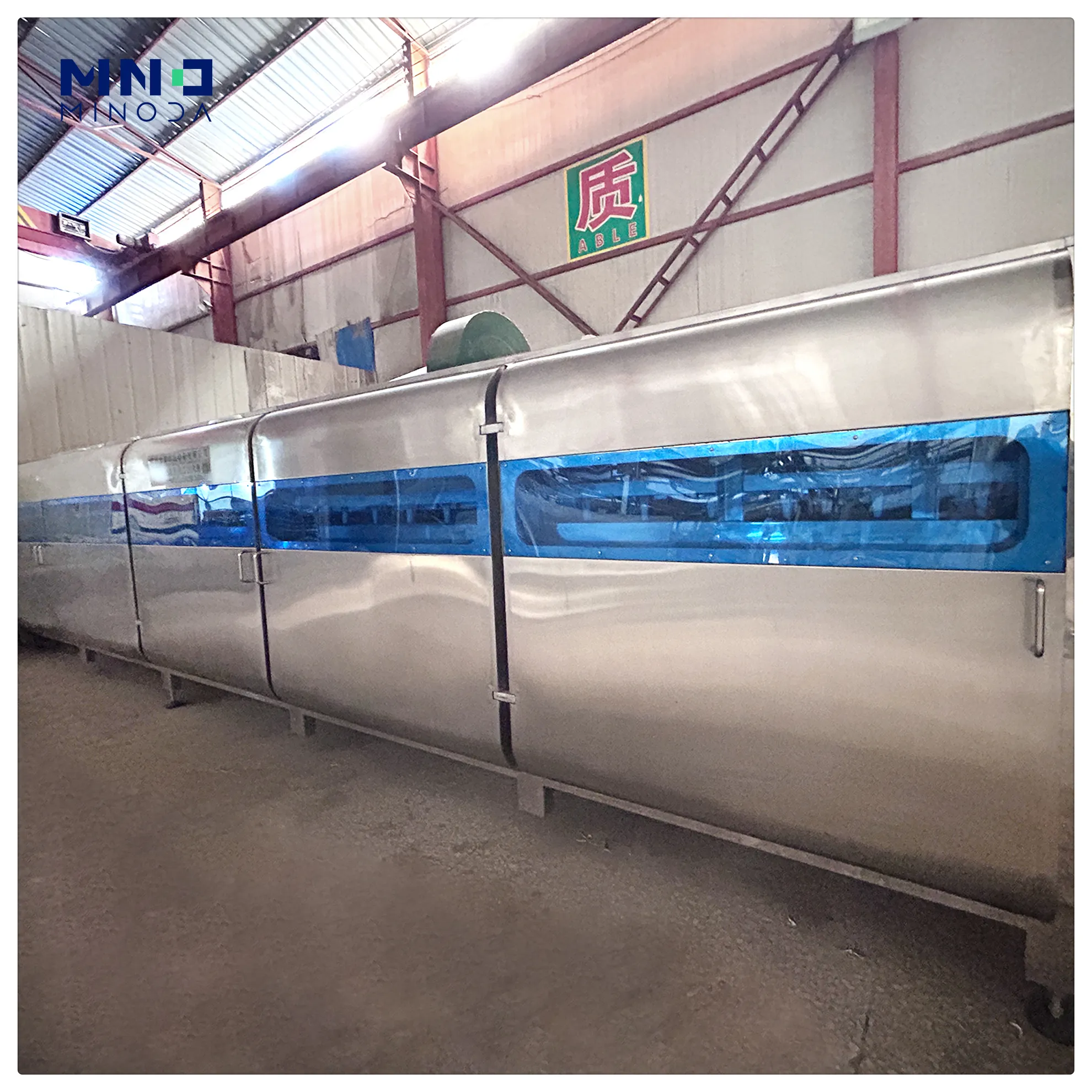

The Premium Non-Fried Noodle Production Line utilizes advanced technology to ensure that the noodles produced maintain superior quality. This results in better texture and taste, appealing to consumers and increasing market competitiveness. Our lines are designed to preserve the natural flavors and nutrients, reflecting the growing demand for healthier food options.